Pharmaceutical Emulsions

The pharmaceutical emulsions should be packed in a suitable container as per the usage. Mainly emulsion is formulated for oral use so it is packed in air-tight bottles.The amber-colored bottle is used for the packing of light-sensitive emulsions.

Wide-mouth bottles are used for the viscous emulsions and a label is mentioned on the emulsion that these products have to be shaken vigorously before they are going to be used.

It should be mentioned on the label that these products are for external use only.

Generally, emulsions should be stored in a cool place. The very low temperature should be avoided because it may affect the stability of the emulsion so, refrigeration should be avoided.

Selection Method of Containers

There are different types of methods through which liquid orals are filled into containers.Read more - Liquid Orals

The selection of filling depends on the following methods;

1. Characteristics of liquid

a) Viscosity

b) Surface tension

c) Qualities of foam producing

d) Compatibility with the construction materials of the filling machine

2. The packaging type

3. Required production output

Filling Methods

Gravimetric Filling Method

In the gravimetric filling method, the liquid is allowed to flow into the container from the bulk liquid tank up to a desired weight.Advantage

For filling a large number of formulations, and also for highly viscous products this filling method is very useful.Disadvantage

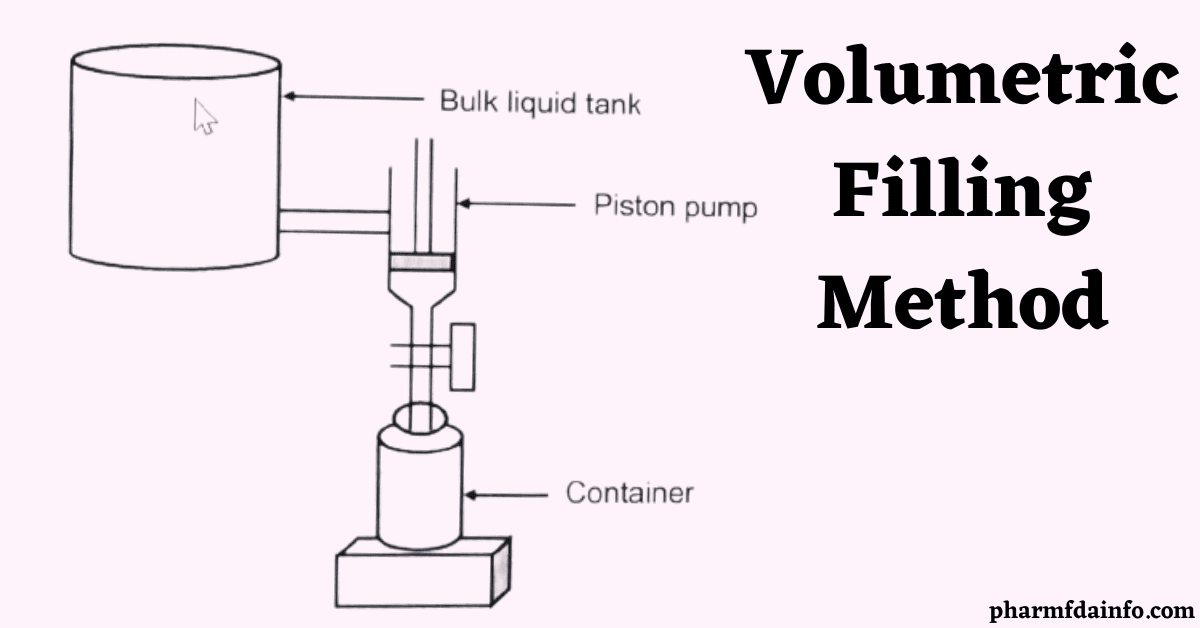

This method is not suitable for automatic equipment as well as for high-speed production rates.Volumetric Filing Method

In the volumetric filling method, the liquid is filled through the positive displacement piston action. A measuring piston and cylinder are present in the filling station. With the help of piston stroke, the required quality of the liquid is filled.Advantage

Within a fraction of a milliliter, the amount of liquid is filled accurately.Disadvantages

The piston may be seized if the liquid is very viscous due to which either loss of accuracy may occur or breakdown of the line may occur.The less viscous liquid flow very fast, this occurs due to the dripping from the filling piston that results in the inaccuracies of filling the solution.

For a uniform appearance, there should be uniform dimensions containers used for filling the solution.

Constant Level Filling Method

In the constant-level filling method, the containers are used for controlling the filling of each unit.The amount that is filled may vary by adjusting the height to which the container is filled.

If variations occur in the container's dimensions then the net fill per unit may also vary.

The filling machines work on the siphon principle. The high-pressure difference is created between the constant level overflow system as well as the liquid discharge nozzle.

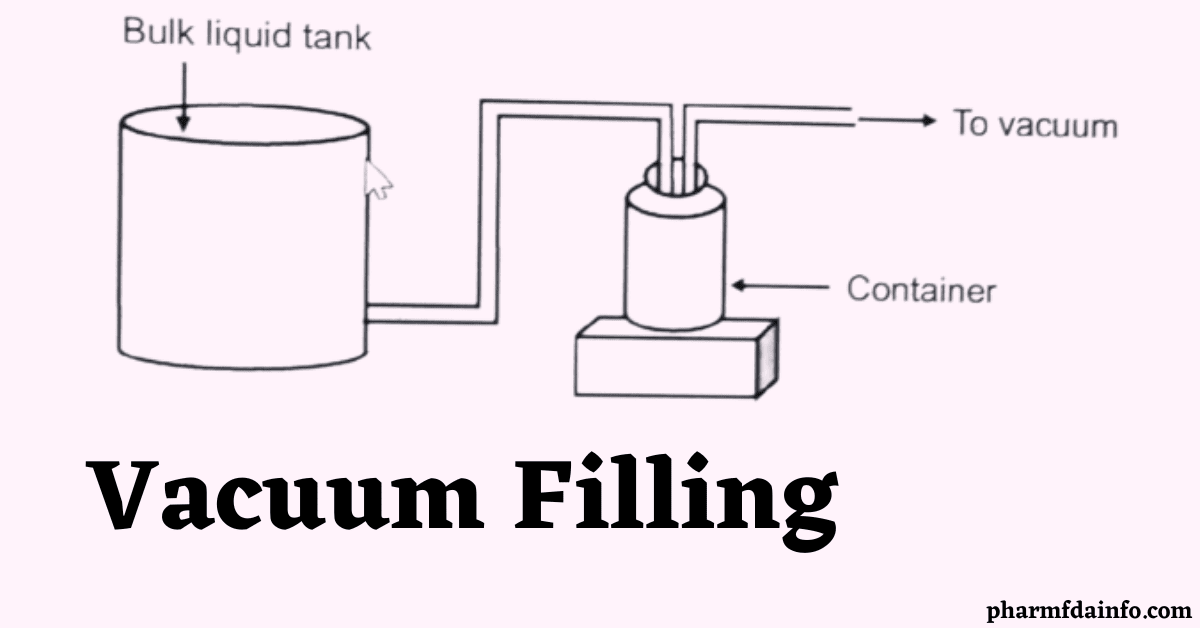

a) Vacuum Filling

In the vacuum filling technique, the container is connected to the bulk liquid tank with the help of a vacuum head.There should be an airtight connection.

On the different side, the container is connected to the vacuum pump.

Now, the vacuum is developed into the container.

Then the developed vacuum starts the flow of liquid from the bulk liquid tank to the container.

Now, the level of liquid starts riding until it reaches the vacuum tube. The vacuum tube is positioned at the required constant level.

If from the vacuum tube, the excess liquid falls then it is recycled through the bulk liquid tank.

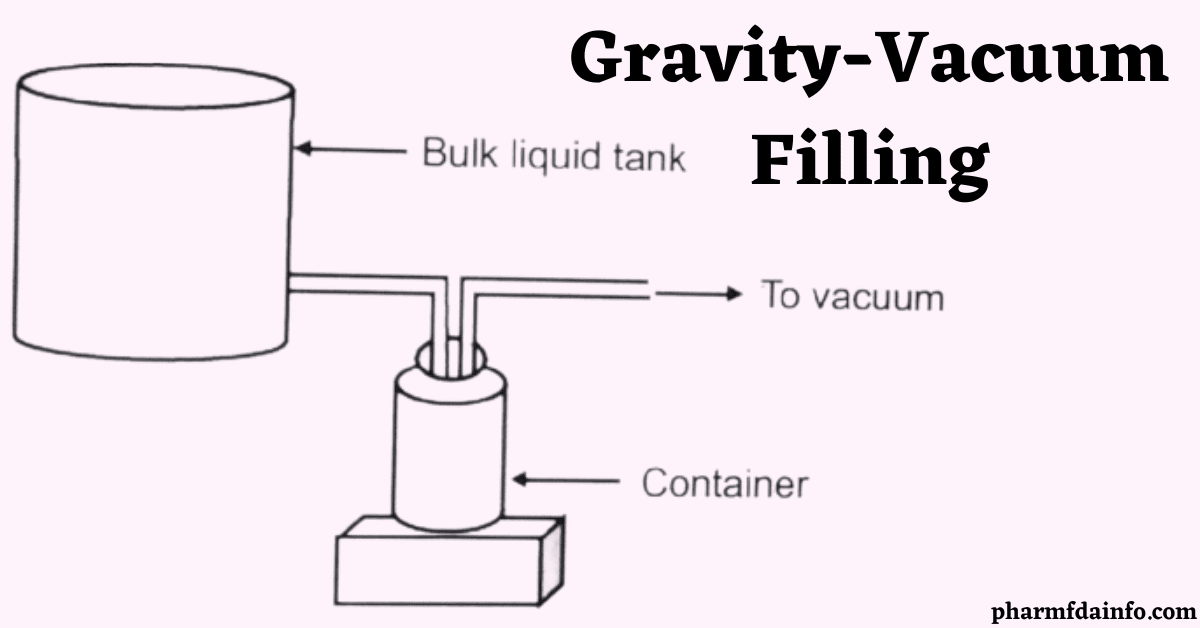

b) Gravity-Vacuum Filling

In the gravity-vacuum filling method, the bulk liquid tank is situated above the container and the connections should be airtight.A vacuum is applied for filling the liquid and gravitational force also plays an important role in filling the liquid.

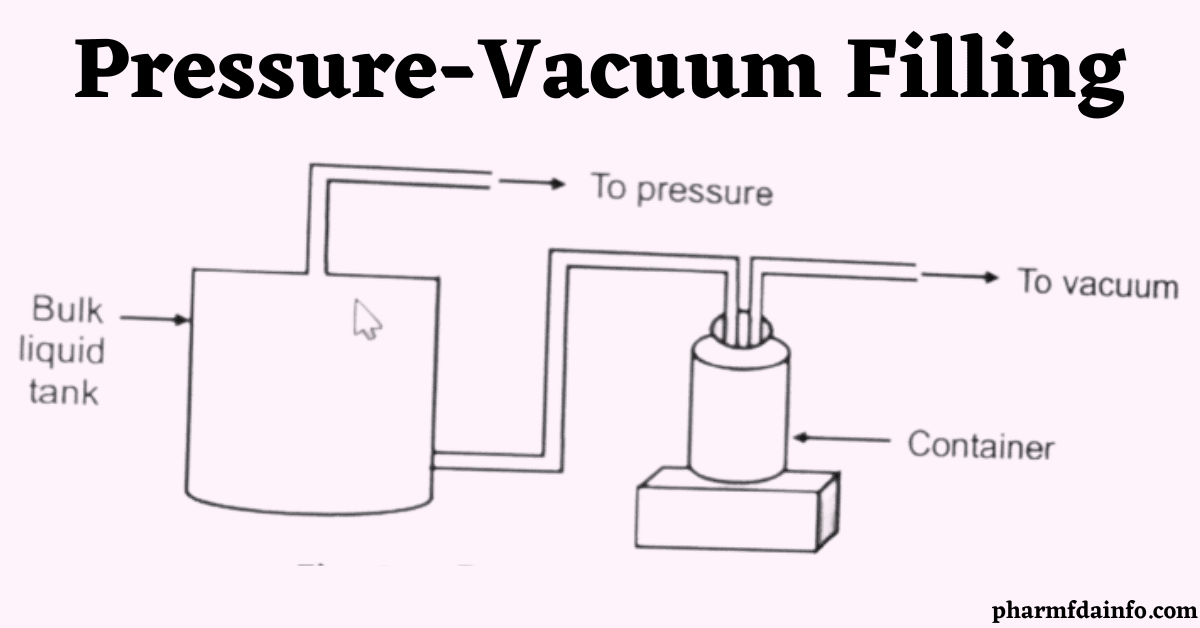

c) Pressure-Vacuum Filling

In the pressure-vacuum filling method, the container is connected to the vacuum pump and the bulk liquid tank is connected to the pump having positive pressure.Both vacuum in a container and positive pressure simultaneously act to fill the liquid.

Advantage

For highly viscous liquids this method is applicable.

Foam Production

While filling the liquids the foam is produced in all methods. When a high production rate is required then this is a very serious problem.The foam formation can not be completely solved. Although it can be minimized by the following techniques;

a) By using such types of equipment that decreases the turbulence.

b) By using various mechanical deforming devices.

c) By using the closed system of filling equipment that prevents the entry of air which may cause foam formation.

d) By using low filling rates.

Package

Generally, maximum liquid oral preparations are either packed in amber color containers or hard glass containers with metal as well as plastic caps.The glass containers are inert to the aqueous solution at a pH range that is suitable for oral liquids but in a few cases, capes and liners may react.

Sometimes plastic caps may be cracked due to contact with a few liquids.

In the same way, metal caps may undergo corrosion.

Hence, it is very important to select a closure that is compatible with the liquid.

I hope you have liked the article on pharmaceutical emulsions and their packaging, labeling as well as storage of emulsions. If you have any point please ask in comment.

Pharmaceutical Emulsions Video Tutorial

FAQ

Ques 1- What are emulsions in pharmacy?In pharmacy, emulsions are generally used for that medication are not dissolved in water but can be dissolved in oil.

Emulsions are also used in the formulation of creams, lotions, and shampoos. These products may contain emulsifying agents which help in providing the stability to these formulations.

Ques 2- What is the process of emulsification?

Ans- Emulsification is the process that helps to minimize the surface tension between the two liquids and also stabilizes the emulsion.

Generally, emulsifying agents are added to the aqueous and then add the oil phase slowly into it with vigorous mixing to form an emulsion.

So the process of emulsification is very important in pharmacy form making a stable and uniform mixture of two immiscible liquids.

Ques 3- Preservation of emulsion?

Ans- Emulsions preservation is an important factor to confirm the effectiveness and stability throughout its shelf life.

There are the following methods through which emulsions can be preserved;

1) By the use of antimicrobial preservatives such as parabens and benzoic acid.

2) By adjusting the pH which may affect its stability.

3) By proper packaging may help in the preservation of emulsions.

4) Emulsions should be stored in dry, cool places and also away from light and heat.

5) To prevent oxidation, antioxidants like Vitamin E can be used.

.png)

0 Comments